Kazuya Akimitsu

Trustee and Vice-President of Kagawa University, Director of the International Institute of Rare Sugar Research and Education

Dr. Akimitsu completed his doctoral course at the Graduate School of Michigan State University in 1992 (Ph.D.). After working as a postdoctoral researcher at the MSU-DOE Plant Research Laboratory for 2 years, he began teaching at the Faculty of Agriculture, Kagawa University in 1994, specializing in rare sugar science and plant pathology. He was appointed the dean of the Faculty of Agriculture in 2021 and has been in his current position since 2023.

Yasuo katta

Executive Officer and Director of R&D Center, Matsutani Chemical Industry Co., Ltd.

Katta graduated from the Department of Agricultural Chemistry, Faculty of Agriculture, Shimane University in 1988. That same year, he joined the employment of Matsutani Chemical Industry Co., Ltd. and was assigned to its R&D Center, where he conducted research and development of starch hydrolysates, resistant maltodextrin, rare sugars, and other related ingredients. He has been in his current position since 2019.

Yusuke Sone

Assistant Director, Industrial Policy Division, Commerce, Industry, and Labor Department, Kagawa Prefectural Government

Sone graduated from the College of Engineering Systems, Third Cluster of Colleges, University of Tsukuba in 2000. After working for a private company for 20 years, he joined the Kagawa Prefectural Government in 2020. Thereafter, he worked in the Crisis Management General Bureau and the Environment and Forestry Department. He has been in his current position since 2025.

In the Rare Sugars Series, we began with the first installment, “What Are Rare Sugars?”, which covered the history of rare sugars and their position in nature. This was followed by a description of the fundamental concept of the “Izumoring” in the systematized production of all rare sugars using enzymatic methods and of its evolution. In subsequent installments, we outlined an overview of the physicochemical characteristics of rare sugar crystalline structures; an overview of rare sugar production methods based on the Izumoring strategy, and the respective enzymes involved. We also covered the development of applications for various rare sugars. In terms of developing rare sugar applications, we introduced the discovery and development of rare sugar drug candidates for medical fields, including those with anticancer, anti-diabetes, and anti-obesity effects, and also those with anti-aging effects for cosmetics. We introduced the functional development of rare sugars for use in food and agriculture as well.

This paper summarizes how industry, government, and academia have collaborated to advance the practical application of research outcomes derived from these developments. Our intent was to assess the impact of industry-government-academia collaboration on the commercialization of rare sugars. To accomplish this, we examined the history of the regional collaborative translation of rare sugar research into practical applications and traced the course of the social implementation of local innovations.

In the Kagawa region, three products that are of white color have long been collectively referred to as “Sanuki Sanpaku” (Sanuki’s three white products). Specifically, these products are “sugar” from sugarcane, “salt” produced in salt fields from Setouchi seawater, and “cotton,” which was expected to show good yields even in coastal lands because of its salt tolerance. Cultivating sugarcane and cotton, crops well-suited to the warm, low-rainfall climate, and producing salt, which involved leveraging the coastal environment's suitability for salt fields, likely involved tremendous hardship before becoming established. Yet these crops and the salt production represent logical regional revitalization innovations. The history of sugar, one of the “three white products” of the Kagawa region, is outlined here.

The Takamatsu Domain, a feudal domain with a stipulated income of 120 thousand koku, was not financially outstanding, having suffered from financial difficulties caused by natural disasters such as drought. Yoritaka Matsudaira became the fifth lord of the domain at age 29 in 1739. At that time, the average person used mirin (a cooking rice wine), honey, amazake (a sweet sake), and dried persimmon as sweeteners. However, sugar was an expensive imported commodity during the period of national isolation in Japan. Thus, research on sugar production was initiated and regarded as a key strategy for rebuilding the domain’s finances. Matsudaira observed that the sugarcane crop prefers a warm climate and is tolerant to drought, requiring minimal irrigation. The following is an excerpt from a book written by Watanabe in 19641: Lord Yoritaka appears to have first invited a specialist from Edo, but he failed, and therefore the lord entrusted the research to his doctor, Genjyo Ikeda, who immediately began the investigation. Gennai Hiraga, a 19-year-old Takamatsu domain retainer born in Shido, Sanuki, Kagawa, assisted Genjyo Ikeda and later moved to Nagasaki and then to Edo. In his book “Butsurui Hinshitsu” (Classification of Commodities) published in 17632, Gennai Hiraga pointed out that sugar was an extremely expensive imported commodity that could be obtained by squeezing the juice from sugarcane grown under Japan’s domestic climate conditions. He also illustrated a method of obtaining syrup by squeezing the sugarcane. His experience in Takamatsu is assumed to be the basis for the work. After Genjyo Ikeda passed away from illness, his student Shukei Sakiyama took over the research and continued work on it for over 50 years. In 1803, Sakiyama reported to the eighth Domain Lord, Yorinori Matsudaira, that he had succeeded in producing white sugar, rock sugar, purple sugar, and frost sugar. Thereafter, Sakiyama proceeded to cultivate sugarcane and produce sugar from sugarcane in the prefecture. The first shipment of the product to Osaka was well received and highly appreciated. It was reported that “Sanuki’s white sugar is as white as snow, tastes good and is comparable to imported counterparts.”

According to “Noumu Tenmatsu,” data compiled by the Ministry of Agriculture and Commerce, and other materials3, the sugarcane crop area in Sanuki was quite small at one chobu (approximately one hectare) in 1790. It had increased dramatically to 1,378 chobu by 1836, demonstrating remarkable development, and had increased dramatically again to 8,000 chobu by 1866. Many years later after Yoritaka’s decision, Sanuki’s white sugar was known for its high quality, good texture, and elegant sweetness. By the latter half of the 19th century, it appears to have been produced in sufficient amounts to meet domestic demand3. The tradition persists even today, and the name “Wasanbon” remains a source of local pride. However, the production of Wasanbon was only seen in the Tosan region (around the current city of Hiketa, Higashikagawa, in Kagawa, the hometown of Shukei Sakiyama). Although the development of white sugar in Sanuki was successful, more hurdles remained to be overcome before the business could be stabilized. Similarly, the results of rare sugar research had to overcome several barriers before it could be used in practical applications. In light of this historical background, sugar-related research has been conducted not only in the Kagawa (Sanuki) region but also at Kagawa University. Various types of collaboration between industry, government, and academia helped overcome these barriers, as described below.

The demand for Sanuki’s white sugar had gradually decreased. After the Meiji Reform, in particular, cheap imported sugar again satisfied most domestic demand, making it difficult to incentivize sugar producers on beet and sugarcane farms in Japan. In this context, efforts were made to produce glucose, a monosaccharide, from starch, a polysaccharide, rather than sucrose, a disaccharide consisting of glucose (D-glucose) and fructose (D-fructose), on an industrial scale using glucoamylase. The goal of this attempt was to use this “starch sugar” (glucose) as a substitute for the sucrose sugar then in use. However, since glucose is only about 70% as sweet as sucrose, these attempts had largely no influence on the market and failed to provide a radical solution4.

At that time, the sugar industry demanded a mass-production technology for fructose, a high-sweetness candidate material that is 1.2-1.5 times sweeter than sucrose and available at equal cost. In 1957, the use of xylose isomerase from Pseudomonas hydrophila to produce D-fructose from D-glucose was reported. This discovery stimulated expectations, particularly in the starch industry. However, its use in food was complicated by the requirement of arsenic for the reaction4,5. To overcome this problem, Professor Emeritus Kei Yamanaka from the Faculty of Agriculture at Kagawa University, discovered that the D-xylose isomerase from a lactic acid bacterium (Lactobacillus brevis) could be used to convert D-glucose to D-fructose without arsenic. Furthermore, he found that increasing the amounts of D-glucose and the enzyme could encourage conversion. The results were presented at a meeting of the Kansai Branch of the Japan Society for Bioscience, Biotechnology, and Agrochemistry held at Kyoto Prefectural University4 in October 1961. The discovery attracted media attention, beginning with an article in Kyodo News in January 1962 and continuing with articles in newspapers and weekly magazines, and even literary and novel magazines such as Bungeishunju and The All Yomimono4. Major newspapers ran great headlines such as “Kagawa University Associate Professor Yamanaka Succeeds in Creating Glucose as Sweet as Sucrose: Bright Industrialization” (Yomiuri Shimbun, published January 13, 1962) and “Sweet Converted Sugar: The Result of Kagawa University Associate Professor Yamanaka’s Research- A Foothold in Domestic Production” (Sankei Shimbun, published January 13, 1962), and these advanced achievements made in Japan began to achieve worldwide recognition. Professor Emeritus Yamanaka went to Michigan State University in the United States for overseas research, where he was advised by Professor W. A. Wood, who later became the president of the American Society for Microbiology. Professor Wood advised him as follows: “You should collect as much physical and biochemical data as possible using crystalline enzymes −enzymes in their pure form, free of impurities− and publish a comprehensive paper.” After returning to Japan in 1965, Yamanaka was promoted to a full professorship and dedicated himself further to research. On the morning of June 14, 1966, he succeeded in crystallizing D-xylose isomerase. Following Professor Wood’s advice, Professor Yamanaka wrote a paper on his results in 19686. He and his colleagues subsequently gained world fame for purifying and crystallizing L. gayonii L-arabinose isomerase7 and other enzymes, and for describing modes of metal ion binding in isomerase reactions. Technical innovations enabled by Yamanaka’s discovery have reduced the cost of producing isomerized sugars from glucose. Currently, sweeteners used in industrial food production have shifted from sugarcane-derived sugars to starch-derived isomerized sugars. In the United States, large amounts of high fructose corn syrup (HFCS) with an even higher fructose contents are sold to carbonated beverage manufacturers and other users.

Isomerase research at Yamanaka Laboratory in Kagawa University continued. Then-assistant Ken Izumori reported on the crystallization of Aerobacter aerogenes D-arabinose isomerase in 19738 and the crystallization of Mycobacterium smegmatis D-ribose isomerase in 19759. He was later awarded Professor Emeritus status at Kagawa University. As he described in his book10, Professor Yamanaka suggested to Professor Emeritus Izumori that he should follow a new research trajectory that was different from the conventional approach. Izumori began to take a new approach to the problem that yielded more than expected results. Born in Tamano, Okayama, Japan, Izumori frequently used Uno-Takamatsu ferries on the major traffic route between Takamatsu−the entrance to Shikoku in the time− and Uno in Okayama prefecture. Thinking outside the box, Izumori took note of the Seto Inland Sea and isolated microorganisms from seawater at depths of several meters (from ferry engine coolant). He obtained D-arabinose isomerase from these microorganisms8,10.

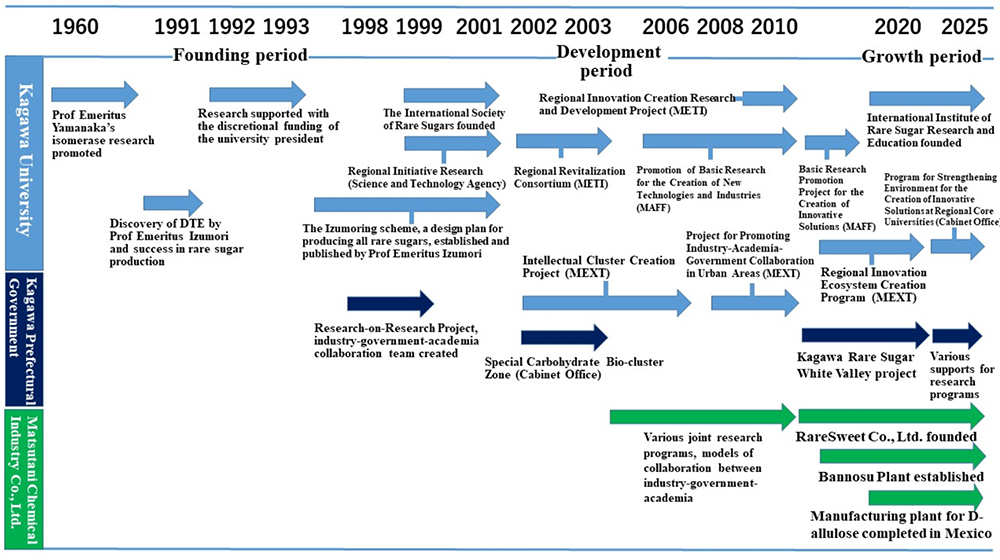

Monosaccharides, including D-arabinose, that occur naturally in only small amounts are called “rare sugars”10. In this series, Chapter 111 describes rare sugars, the research target molecules of Professor Emeritus Izumori, and their position in nature. The chapter also recounts the origin of the term “rare sugar.” Chapters 2 and 4 provide detailed information about the discovery of the first key enzyme used for rare sugar production from microorganisms, i.e., D-tagatose 3-epimerase (DTE) in 1991, and the establishment of the “Izumoring” strategy, a design plan for producing all rare sugars (Figure 1)11,12.

These groundbreaking discoveries were not widely accepted initially. It took a long time to realize the significance of and reason to produce monosaccharides, which occur naturally in only small amounts. Izumori describes the difficulties in his book10. During that period, however, the significance of the achievements was clearly understood by four researchers: Professor Vandamme at Ghent University in Belgium, Professor Leisola at the Helsinki University of Technology in Finland, Professor Saisamorn at Chiang Mai University in Thailand, and Professor Fleet at the Oxford University in the United Kingdom. On April 10, 2001, ten years after the discovery of the first enzyme used to produce rare sugars (Figure 1), the International Society of Rare Sugars headquartered in Kagawa University was founded with approximately 10 members under the auspices of the four researchers.

The significance of Professor Emeritus Izumori’s rare sugar research in its early stage was understood by successive Kagawa University presidents. At first, his basic research did not lead to the acquisition of external funding, but its importance was recognized, and research funding was continued at the university presidents’ discretion (Figure 1). These activities led to the Research-on-Research project by the Science and Technology Promotion Foundation (currently the Kagawa Industry Support Foundation), an affiliate organization of the Kagawa Prefectural Government (1998), the Science and Technology Agency’s Regional Initiative Research (1999-2001), the Japanese Ministry of Economy, Trade and Industry’s (METI’s) Regional Revitalization Consortium (2002-2003), and the Japanese Ministry of Education, Culture, Sports, Science and Technology’s (MEXT’s) Intellectual Cluster Creation Project, a major milestone for the Kagawa district (2002-2006) (Figure 1). These organizations played respective roles as follows: During the presidential discretionary research period, researchers at Kagawa University discussed the various potential applications for rare sugars, particularly in foods and healthcare. Based on the discussion, an industry-government-academia collaboration team for rare sugar production and utilization was formed within the framework of the Research-on-Research project. The Regional Initiative for Research began accumulating basic knowledge about the beneficial functions of rare sugars. Based on these results, the Regional Revitalization Consortium started developing production technologies using bioreactors beyond the laboratory level. These achievements formed the fundamental basis for the Intellectual Cluster Creation Project. This founding period represented the developmental stage of research seeds visualized in the summary of rare sugar research (Figure 1). Key points included establishing a regional system for industry-government-academia collaboration beginning in 1998 and gradually accumulating innovative ideas of Kagawa University. Thus, this period can be described as one in which efforts to transition to practical applications began quietly.

In terms of the number of business sites and employees, Kagawa’s industrial base can be characterized as consisting of approximately 50% core manufacturing technology and food industries, with a broad range of fields covered, mainly by small- and medium-sized businesses, including the production of many products in top niche fields such as print substrate surface treatment agents, isotropic high-density graphite, frozen cooked foods, construction cranes, iron nets, telecommunication cables, gloves, and fans. As described above, the relationship of Kagawa Prefecture to sugars has been profound. In particular, it is noteworthy that the Research-on-Research project in 1998 triggered the formation of an industry-academia-government collaboration team for rare sugar production and utilization (Figure 1). That team worked on the MEXT’s Intellectual Cluster Creation Project (2002-2006), headed by the Governor of Kagawa. During the project, basic research data for rare sugar mass production core technologies and functionalities were compiled. Kagawa University, has achieved remarkable successes as well, including the opening of a rare sugar production station, the founding of the Department of Rare Sugar Science in its Graduate School of Agriculture (master course), and the founding of the Rare Sugar Production Technology Institute, LLC, a university venture enterprise (Figure 1). Furthermore, the Kagawa Prefectural Government played major roles in activating rare sugar research inside and outside Japan, including support for international symposiums of the International Society of Rare Sugars, founded in 2001. In 2002-2003, a rare sugar project strategic committee was created in the METI’s Regional Revitalization Consortium, and regional systems for the establishment of basic technology for D-allulose production, including the “Special Carbohydrate Bio-cluster Zone” system as the first Cabinet Office Special Structural Reform Zone system, were organized (Figure 1)13. Because commercialization progressed slowly during the Intellectual Cluster Creation Project, the rare sugar research program failed to be selected in the second period of the project, so enterprises in Kagawa became less involved toward the end of the first period. However, the program was selected as a Project for Promoting Industry-Academia-Government Collaboration in Urban Areas (2008-2010) in 2008 (Figure 1). Matsutani Chemical Industry Co., Ltd. (hereinafter, Matsutani Chemical), the largest manufacturer of functional modified starches, was initially not located in Kagawa but opened a sales subsidiary there and decided to build a plant for producing syrups containing rare sugars in Kagawa in 2010. In addition to the technical collaboration with Kagawa University, the Kagawa Prefectural Government has been proactive in attracting facilities to Kagawa. An investment in the construction of a large plant with a 1000-ton monthly production capacity was made, followed by a further capital investment in 2016. In 2009, efforts by METI’s Regional Innovation Creation Research and Development Project (2009-2010) advanced the development of rare-sugar-containing syrups (Figure 1). This can be considered the developmental stage during which industry-government-academia collaboration began to yield specific outcomes of development.

Furthermore, in the Kagawa Industrial Growth Strategy formulated as a ten-year plan by the Kagawa Prefectural Government in 2013, the formation of a rare sugar cluster was clearly specified in the first of six key growth fields: “Distinctive food and biotechnology-related fields utilizing regional resources and traditional technologies.” As its first priority in this field, the “Kagawa Rare Sugar White Valley” project was launched (Figure 1). The project had three aims: 1) Based on a "knowledge base formation" scheme, rare sugar research was strengthened through industry-government-academia collaboration, and research outcomes were announced at the International Symposium of International Society of Rare Sugars, 2) Based on a "Rare sugar industry creation" scheme, the formation of industrial infrastructure was promoted, the development of new products was supported, and an industry-government-academia collaboration network was formed, and 3) Based on a "Kagawa rare sugar brand establishment" scheme, public awareness that “rare sugars = Kagawa” was increased through various trade shows, fairs, and other events, and the worldwide branding of “Kagawa’s rare sugars” was promoted. As this project proceeded, production and multifaceted application of developments in Kagawa University progressed, and an intellectual property strategy was established. Additionally, a robust industry-government-academia collaboration network and an upstream-to-downstream commercial flow were established. Furthermore, public awareness of rare sugars increased, and their market expanded gradually. To develop applications in a broad range of industries, Kagawa University founded the International Institute of Rare Sugar Research and Education as a university-wide organization in 2014. For 10 years from the founding, around 80 professors from all faculties of the university conducted approximately 60 research programs. The Institute received the 12th Ministry of Education, Culture, Sports, Science and Technology’s Award in the Regional Industry Support Program Commendation Program in 2023. The same year, a “Regional Collaboration Department” and “Commercialization Promotion Department” were newly established in the Institute to facilitate further regional collaboration. To quickly link its achievements to commercialization, support programs for the commercialization of Kagawa-based enterprises were launched, and industry-government-academia collaboration for the creation of new industries is currently ongoing. This was the developmental period of rare sugar research (Figure 1), in which the close industry-government-academia collaboration began to accelerate the development and expansion of new rare-sugar-based markets.

Many companies are involved in the development of rare sugar applications, among which we would like to introduce Matsutani Chemical, a partner with Kagawa University in rare sugar production. Here, we review the history of this collaboration with this largest manufacturer of functional modified starches in Japan. Headquartered in Itami, Hyogo, Japan, Matsutani Chemical was founded in 1919 as a pioneer in the commercial modified starch industry. Its key product, resistant maltodextrin, is a functional ingredient developed from starch as the starting material and is well known to be a food for specified health uses (FOSHU) and foods with function claims (FFC).

In the spring of 2003, the late Eijiro Matsutani (president of the company at that time) saw rare sugars on a TV news program and intuited their potential use as food ingredients. He said to his subordinates, “Go to Kagawa University and get information on rare sugars.” In response, the director of the company’s R&D Center and the Manufacturing Department Manager visited Kagawa University. This was the first step on the long collaborative road to commercialization of rare sugars. At that time, the aforementioned Intellectual Cluster Creation Project was already in operation (Figure 1), and Kagawa University and the Kagawa Prefectural Government were forming an industry-government-academia collaboration team focusing on Kagawa-based enterprises. They were therefore somewhat reluctant to invite enterprises from outside the prefecture. However, the company had obtained FOSHU certification for its resistant maltodextrin, and only a few enterprises in Kagawa had the knowhow or experience necessary for mass-producing and commercializing rare sugars as food ingredients. Therefore, its entry into the market was inevitable. In 2010, Matsutani Chemical founded RareSweet Co., Ltd. to sell rare sugars and facilitate their spread in Kagawa, thus joining the program as a Kagawa-based enterprise. Furthermore, in 2013, a large-scale plant was opened in the Bannosu Waterfront Industrial Park at Yoshida, Utazu, on the Kagawa side of the Seto Ohashi Bridge (Figure 1). In 2011, the company began small-scale production and marketing of a syrup containing D-allulose and other rare sugars. In 2013, it opened a plant of large capacity and began large-scale marketing. Furthermore, in 2019, a plant for manufacturing D-allulose was completed in Querétaro, Mexico, as the world’s first manufacturing facility to mass-produce pure rare sugar, in collaboration with a company in the United States (Figure 1). The company manufactures an enzyme for D-allulose production at its Bannosu Plant in Kagawa and exports it to its Mexico Plant, where “ASTRAEA®” (a registered trademark for D-allulose, marketed with distinction from competing products manufactured in other countries in the company’s branding strategy) is produced using the enzyme. By March 2025, more than 750 Japanese companies had used D-allulose to produce more than 3,700 products, and D-allulose became commercially available in at least 15 other countries; international competition since the start of global development has been increasingly intense.

In this way, the practical application of rare sugars to the food field began by establishing D-allulose mass-production technology and procuring raw materials at the lowest cost to find larger markets. In 2021, Kagawa University and Matsutani Chemical received the Technical Development Award from the Japanese Society of Applied Glycoscience for their extensive research into D-allulose mass production technical development and practical application. However, increasing numbers of rare sugar applications have been found, not only in the food field but also in the healthcare, agricultural, and industrial fields, and research has been conducted to determine which of the approximately 50 rare sugars are best suited for what applications. In this situation, it became necessary to establish production technologies for rare sugars other than D-allulose and secure basic intellectual properties. For this reason, the industry-government-academia collaboration in the MEXT’s Regional Innovation Ecosystem Creation Program as adopted in 2017 (Figure 1) tried on numerous occasions to establish production technologies for various rare sugars and develop new applications. In conjunction with this trend, fundamental concepts for the development of agricultural materials that are distinct from conventional concepts were established by the Ministry of Agriculture, Forestry and Fisheries Promotion of Basic Research for the Creation of New Technologies and Industries (2005-2010) and Basic Research Promotion Project for the Creation of Innovative Solutions (2011-2013) (Figure 1). Furthermore, the Cabinet Office Program for Strengthening Environment for the Creation of Innovative Solutions at Regional Core Universities (2023-2025) promoted collaboration with regional enterprises to facilitate development in the healthcare, agriculture, and industrial sectors (Figure 1); there has been steady progress toward practical applications at different speeds in different industrial fields.

As one might imagine from their sweetness, rare sugars were first commercialized in the food industry and are expected to find applications in a broad range of other fields. Kagawa University's faculty has efficiently conducted collaborative research across academic fields through the International Institute of Rare Sugar Research and Education. These initiatives have introduced research findings in diverse fields, including food, medicine, anti-aging, and agriculture. Trial tests are progressing in various industries, including replacing current sugars with rare sugars based on the potential applications of several rare sugar characteristics. The pace of progress varies by industrial field. For instance, global development has already begun in the food industry and will soon begin in agriculture. Research has just begun in the anti-aging field, and activities to achieve long-term goals are underway in the healthcare field. Research development progresses in parallel across various fields on different timelines. Since developments in one field follow those in another, the societal implementation of rare sugars is expected to be highly sustainable in the long term. A close relationship between industry, government, and academia has been crucial in the long history of rare sugar research. An approach that makes the best use of their strengths is paramount for social implementation. This final paper in the series in the present journal describes the history of the role of the industry-academia collaboration in the development of rare sugars. While not mentioned in this paper, collaboration partners include not only local governments and particular enterprises, but also national entities. The ongoing research and development of practical applications of rare sugars is supported nationally through the close collaboration of many companies in various industrial fields. We would like to take this opportunity to express our gratitude to all those involved. This paper is the last in the series exploring rare sugars. We hoped that future advances in rare sugar research and development will be reported in non-periodic issues.

The authors express our gratitude to everyone who contributed to the preparation of this manuscript.